Book Service / Repair

Remote Support

Authorised Verifier

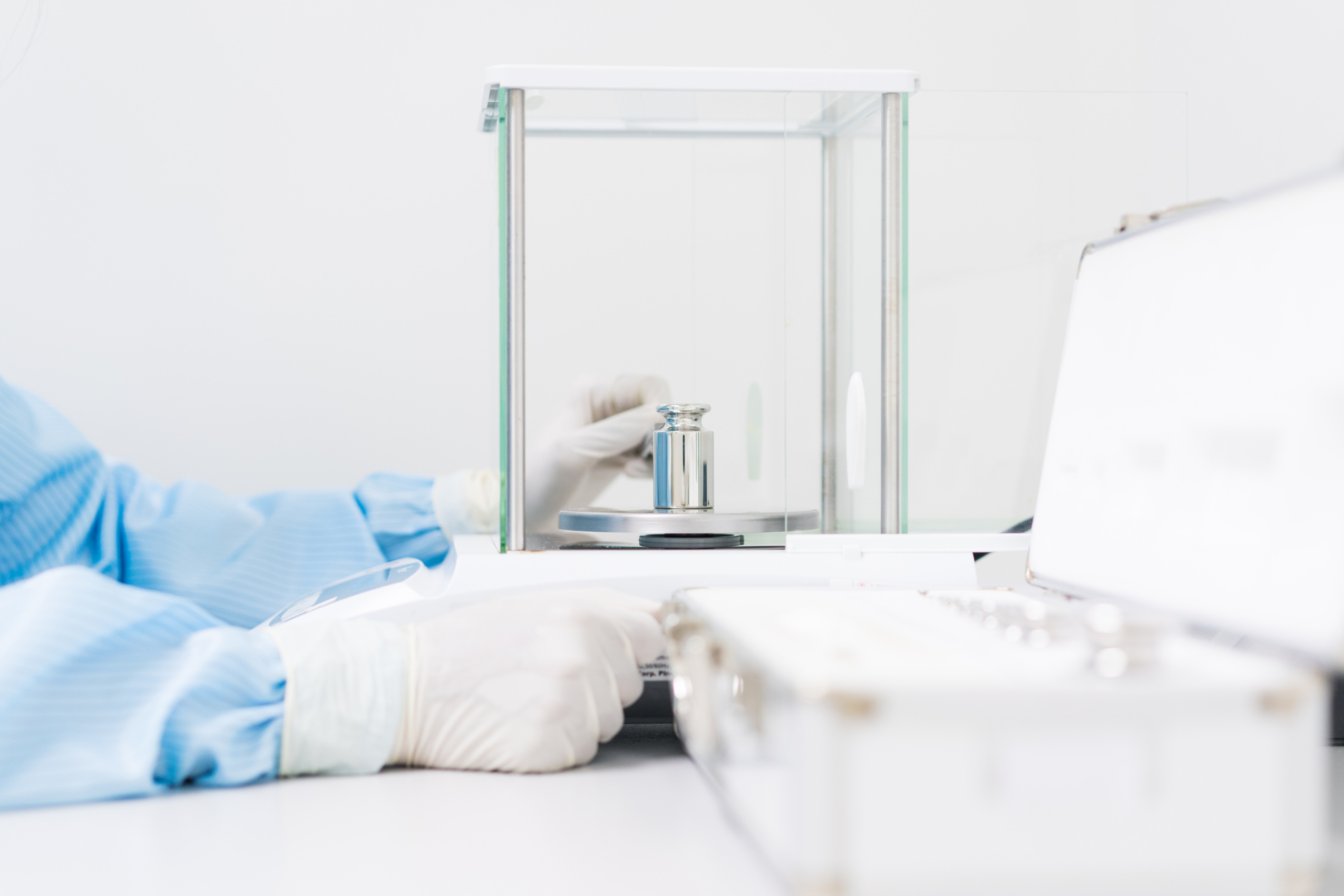

Calibration

Weighing Machine Services offers a full calibration service which can be carried out in your own premises or in our factory. Calibration is a process in which we check that you’re scales is weighing correctly. It is carried out using several weights some of which are certified by NSAI legal metrology services. Our technicians have access to over 60 certified test weights ranging from 100mg F2 certified weights to 20kg M1 certified weights. Our test weights are regularly re-certified to insure they are accurate.

Before we start the calibration process, we will check to ensure that the weighing environment is suitable for the scales. This includes but is not limited to checking the scales is level, on a firm flat surface, without vibration or wind interference. The scales will be checked for any obvious signs of damage this will include the power cable if fitted. The scales will be powered on and allowed to zero before a repeatability test is carried out. A repeatability test insures that the same set of weights displays the same reading each time after the weight has been removed & placed back on the scales several times.

Now we will carry out a corner test in which we test the scales weighs correctly in each of its corners. This test is carried out with a maximum weight of only 25% of the scales weighing capacity as no more than this weight should ever be weighed in a single corner of a scales.

Finally we will carry out a linearity test. This test will check the scales is weighing correctly in the center of the weighing pan in at least 5 points of the weighing range. We will report our findings on our calibration cert. A calibration adjustment of the scales if required will be carried out to adjust the scales to weighing correctly. If a calibration adjustment was required then a complete test as above is carried out and the new results of our test results will be recorded.

In some cases during a calibration process the scales will be found to have damaged parts. In these cases, the customer will be asked if they would like a repair carried. if the cert will be issued showing the errors and detailing the fail with the scales.

It is recommended to have your scales externally calibrated at least once a year and, in some cases, where the scales is used constantly it should be carried out every six months.

Book Fishing Scales Calibration

If you are a member of any fishing club Weighing Machine Services Ltd will offer you a discounted price of €40.65 (€50, Including VAT of 23%) to have your fishing scales calibrated. Calibration are required if you are entering into fishing competitions, and should be completed every year. This reduced cost is only for calibrations carried out in our factory and does not include the cost of delivery or collection if required. Calibrations of fishing scales are normally completed within one to two working days from the date received by us. A calibration sticker, calibration certificate for scales, calibration certificate for weights used and VAT invoice will be included with every calibration.

Pay Online

Short Term Hire

Hire of Counting Scales

We have available for hire a large selection of counting scales for short term hire. These scales are mostly used by companies to carry out a stock checks of all their components. It can be cheaper to simply hire a counting scales for the week of the stock take rather than to buy, maintain & calibrate them. Hire of a basic desktop counting scales is €60 per week (or part). This price does not include delivery or collection. Contact us with the details of your project and we will recommend a scales to suit your needs.

Hire of Retail Shop Scales

We offer hire of retail shop scales with printers & cash boxes if required. This can be handy for customers who want a extra scales for a busy holiday such as Christmas. We can also supply scales & weighing EPOS system for hire to POP UP shops or markets. Please contact us for more details.

Hire of Movie Props

We have a very large range of vintage weighing scales which are possible to hire for use in the movie business. We supplied the scales for Biddy Byrne’s Fruit & Veg shop in Glenroe. Contact us for more information and pricing information.

Vintage Scales

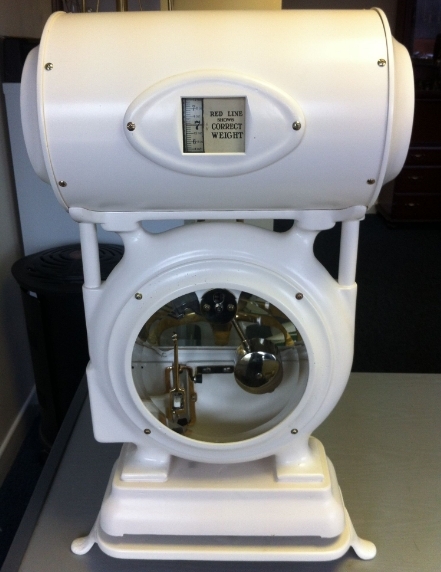

Avery scales

This is an Avery scales that was in Nutgrove Shopping Centre for many years. It is coin operated, which allowed customers weigh themselves for a small fee. This machine was originally manufactured in the 1950’s in the UK and was sold to the likes of Woolworths for their chain of supermarkets throughout the UK & Ireland. The scales could weigh up to a maximum of 24 stone. The scales were originally imported into Ireland and supported by H Evans and sons. Today there are virtually no other companies other than ourselves that could repair the scales due to lack of parts. Back in December 2014 the owners of The Nutgrove Shopping Centre asked Paddy Leonard to repair the scales so it could be used once again, the scales was restored into service but sadly is no longer located in the Shopping Center public area.

W&T Avery 20lb mechanical Scales

This is a W&T Avery 20lb mechanical pendlum type price computing scales. In 2015 we purchased from a customer who had it in his shed for years. The scales was originally manufactured in Birmingham England. Paddy (Our Managing Director) took great care in dismantling the scales so he could send the external parts for powder coating. While dismantling the scales we found the date stamp of manufacture which dated 14th Dec 1928. It is believed that this type of scales was the first price computing scale sold in Ireland. Scales before this would just weigh and the user would then calculate the sale price of the piece of meat to be sold. It could weigh up to a maximum of 20 pounds with a price range per Lb from 4 pence to 3 shillings and Sixpence. The scales is also unique because it didn’t use springs which had a tendency to stretch overtime causing the customer to get wrong lighter weight readings. The scales has a lead seal which the government would stamp after inspecting the scales was weighing correctly each couple of years.

Avery 20lb semi automatic Scales

This is an Avery 20lb semi automatic price computing scales, with a price range per Lb from 4 pence to 3 shillings and Sixpence. Without the use of external weights the scales could only way up to 1 pound. if you needed to weigh something heavier than a pound you would place external weights on the left side. This is why the scales was called semi automatic. If you placed a 2lb weight on the left and the chart showed 4oz then the weight on the scales would be 2lb 4oz’s. If a 5lb weight was on the left and the chart read 10½ Oz’s then the weight of meat or product on the right of the scales would weigh 5lbs 10½ Oz’s. The price shown on the scales was only the price for the weight under the first 1lb. To work out the price of a 5lbs 10½ Oz’s piece meat the butcher would have to multiply his price per LB by five and then add the extra amount showing on the scales chart to get the total amount due. This was usually walked out with pencil and paper and in a lot of cases was worked out on the paper that the meat was wrapped in.

Service Videos

Coming Soon

We are will be adding some service videos here for to help you do the simple things like changing a roll of labels, Removing a label from the printer head or even fitting a new printer head.